Artificial Intelligence (AI) has rapidly evolved from a theoretical field to a transformative force across multiple disciplines of engineering. As the demand for smarter, more efficient systems increases, AI has been integrated into various engineering applications—reshaping robotics, optimizing manufacturing processes, and revolutionizing civil engineering practices. The fusion of AI with traditional engineering domains has led to significant efficiency gains, risk mitigation, and predictive capabilities that were unimaginable just a decade ago.

AI in Robotics

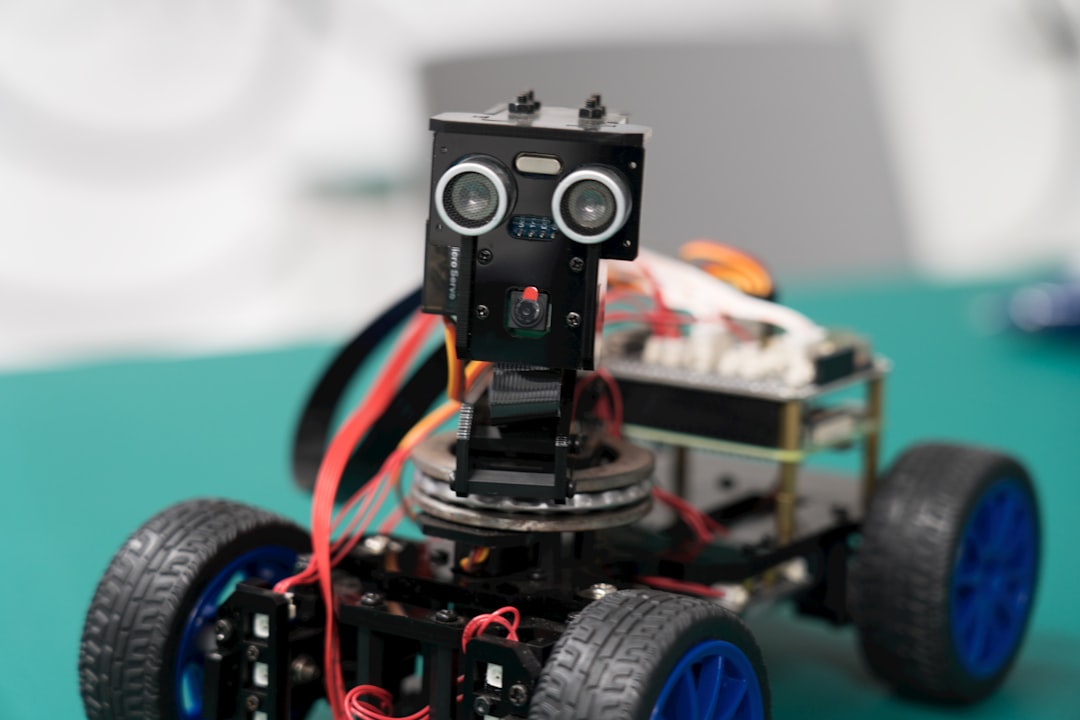

Robotics has been one of the most active and fruitful grounds for AI implementation. From autonomous navigation to intelligent sensing and decision-making, AI algorithms empower robots with the ability to operate in dynamic and often unpredictable environments.

1. Autonomous Navigation Systems

One of the most visible applications of AI in robotics is autonomous navigation. AI-powered robots utilize machine learning, computer vision, and sensor fusion to navigate complex terrains and perform tasks with minimal human input. These technologies are commonly used in environments such as:

- Warehouse logistics: Robots navigate autonomously through storage facilities to retrieve and transport goods efficiently.

- Search and rescue operations: Drones equipped with AI can identify human heat signatures and maneuver through debris to locate survivors.

2. Human-Robot Collaboration

The development of cobots, or collaborative robots, showcases how AI fosters human-machine synergy. These robots are equipped with real-time sensory feedback and machine learning capabilities, allowing them to work safely alongside human operators on the production floor. AI enables cobots to learn from human behavior, anticipate actions, and continuously improve their performance.

3. Adaptive Control and Learning

AI algorithms have paved the way for adaptive control systems in robotics. Rather than relying on predefined rule sets, adaptive control learns from data derived from sensors to dynamically adjust robotic movements. For instance, a robotic arm in a manufacturing setting can modify its path based on resistance or unexpected shifts in the environment, improving precision and reducing errors.

AI in Manufacturing

The manufacturing industry is undergoing a profound transformation through the integration of AI technologies. Often referred to as the fourth industrial revolution or Industry 4.0, smart manufacturing combines AI, the Internet of Things (IoT), and advanced analytics to build intelligent and automated production environments.

1. Predictive Maintenance

One of the most economically beneficial applications of AI in manufacturing is predictive maintenance. By analyzing historical equipment data and real-time sensor inputs, AI models can predict when a machine is likely to fail. This allows facility managers to schedule maintenance proactively, reducing unplanned downtime and extending the lifespan of assets.

- Reduces unscheduled downtime by up to 50%

- Lowers maintenance costs significantly

- Enhances overall operational efficiency

2. Quality Control Using Computer Vision

AI-driven computer vision systems are replacing traditional quality control methods with unparalleled accuracy and speed. Cameras powered by machine learning algorithms can detect even minute anomalies in products—such as blemishes, misalignments, or incorrect assembly. These systems can adapt over time to improvements in production quality, reducing waste and improving customer satisfaction.

3. Demand Forecasting and Supply Chain Optimization

Using AI for demand forecasting enables manufacturers to manage inventory more effectively, reduce costs, and streamline supply chains. AI models analyze vast datasets—including historical sales trends, market fluctuations, and even weather patterns—to predict demand accurately. When combined with IoT systems on the manufacturing floor, this ability makes real-time adjustments to production schedules possible.

4. Process Optimization and Digital Twins

Through the use of digital twins—virtual models of physical processes—AI empowers engineers to simulate, monitor, and improve manufacturing operations without interfering with the actual production line. These digital replicas are continuously fed with real-time data, allowing for process optimizations that enhance throughput and reduce energy consumption.

AI in Civil Engineering

Traditionally considered a “low-tech” discipline, civil engineering is increasingly adopting AI technologies to improve infrastructure planning, construction, and maintenance. As urbanization accelerates and climate events become more unpredictable, AI provides critical tools for ensuring resilience and efficiency in civil infrastructure.

1. Smart Construction Techniques

AI is instrumental in automating and optimizing construction processes. Machine learning models help in generating realistic project timelines by analyzing historical data about past projects, equipment downtime, and labor availability. In addition, AI-powered robotics is used in:

- Bricklaying and 3D concrete printing

- Autonomous grading and excavation

- Site inspections using drones

These innovations not only accelerate the construction process but also enhance safety on job sites by taking humans out of hazardous environments.

2. Infrastructure Monitoring and Maintenance

One of the vital contributions of AI in civil engineering is the use of sensor data and computer vision to monitor infrastructure health. Bridges, tunnels, and highways are embedded with sensors that collect information on vibrations, strain, and temperature. AI then analyzes this data to detect structural fatigue, corrosion, or unusual wear patterns.

For example, some transportation authorities are using AI to monitor bridge safety in real-time and alert engineers to early warning signs before they manifest into catastrophic failures.

3. Urban Planning and Traffic Management

AI is also improving the way cities are designed and operated. Through predictive models and simulation software, urban planners can visualize how different design choices affect future traffic patterns, pollution levels, and energy use. AI applications include:

- Smart traffic signals that adapt to congestion in real time

- Optimizing public transport schedules based on commuting habits

- Forecasting growth and resource demands in urban areas

Challenges and Considerations

While the benefits of AI integration are well-documented, it is important to approach its implementation with a measured perspective. Engineering professionals must account for several key challenges:

- Data Quality: AI models are only as effective as the data they are trained on. Incomplete or biased data can lead to incorrect outcomes.

- Security Risks: As systems become more connected, cybersecurity becomes an essential consideration, particularly in sectors like civil infrastructure and manufacturing.

- Ethical Concerns: The automation brought by AI may result in job displacement, requiring a focus on retraining and workforce adaptation strategies.

Conclusion

The integration of artificial intelligence across engineering disciplines is reshaping the profession and setting new benchmarks for efficiency, safety, and innovation. In robotics, AI brings autonomy and intelligence to machines once limited by rigid programming. In manufacturing, it enhances productivity, quality, and predictive maintenance strategies. In civil engineering, it enables smarter infrastructure, safer construction, and more livable urban environments.

As with any powerful tool, the successful application of AI in engineering requires a judicious combination of technical expertise, ethical awareness, and continuous learning. Engineers are no longer just builders of physical systems—they are architects of intelligent systems designed to adapt and evolve alongside society’s most pressing needs.

logo

logo